Lldpe Stretch Film For Pallet Packing

Lldpe Stretch Film For Pallet Packing Specification

- Thickness

- 23 microns

- Size

- 500 mm x 400 m

- Usage & Applications

- Pallet Packing, Wrapping, Packaging and Securing Goods

- Material

- LLDPE (Linear Low-Density Polyethylene)

- Load Capacity

- Medium to Heavy Duty

- Eco Friendly

- Yes, recyclable

- Print Type

- Plain / Unprinted

- Water Resistant

- YES

- Coating Type

- No Coating

- Color

- Transparent

- Finish Type

- Glossy

- Closure

- Cling/Self-adhesive

Lldpe Stretch Film For Pallet Packing Trade Information

- Minimum Order Quantity

- 200 Kilograms

- Supply Ability

- 1000 Kilograms Per Week

- Delivery Time

- 7 Days

About Lldpe Stretch Film For Pallet Packing

LLDPE STRETCH FILM FOR PALLET WRAPPING

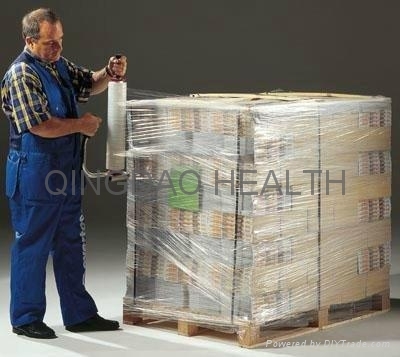

We offer high quality lldpe stretch film. Stretch film is a plastic film used to secure, bundle, and stabilize products. Stretch film is made from linear low-density polyethylene. The main role of wrapping a full pallet to prevent product damage during transportation. Pallets that differ in weight and height can change the amoun of film needed. Another factor is the type of stretch film being used. This will directly determine the amount of film needed as well as the amount of braking tension by the user

Superior Protection and Clarity

Engineered with high tensile strength and clarity, the LLDPE stretch film ensures both durability and visibility for packaged goods. Its excellent puncture and tear resistance maintain the integrity of your pallets throughout transit and storage. The glossy, transparent finish enhances product presentation, making it ideal for showcasing contents while protecting them from dust, moisture, and handling damage.

Multiple Sizes, Flexible Application

This stretch film is available in various widths and lengths, catering to different packing requirements. Its core diameter fits standard 3-inch dispensers, and the film can be applied either by hand or with automatic wrappers. Strong cling properties and adaptability make it a reliable choice for diverse packaging operations, including heavy and irregularly shaped loads.

Eco-Friendly and Efficient Packaging

Manufactured from recyclable LLDPE material, the film is an environmentally conscious solution for packaging needs. It is odorless, produces no residue due to its no-coating design, and can be reused, reducing waste. Storing the film in a cool, dry place away from sunlight helps maintain its quality for repeated usage. Designed for efficiency and sustainability, it aligns with modern packaging standards.

FAQs of Lldpe Stretch Film For Pallet Packing:

Q: How do I properly use the LLDPE stretch film for pallet packing?

A: The stretch film can be applied by hand or with a machine wrapper. Simply position the film roll on the core, secure the films leading edge to the pallet, and wrap tightly around the goods. Overlap each layer to achieve optimal security, making sure to stretch the film to benefit from its high elongation rate and excellent cling properties.Q: What are the benefits of using high-clarity LLDPE stretch film for packaging?

A: High-clarity LLDPE stretch film allows for easy visual identification of goods, which helps in inventory management. Its transparency is complemented by excellent tear and puncture resistance, ensuring packages remain secure and intact during transportation and storage.Q: When should I choose manual vs. machine application for this stretch film?

A: Manual application is suitable for small-scale or irregular loads, offering flexibility and control. For large-scale packing, machine application ensures consistent tension and faster wrapping, improving efficiency for high-volume operations. The films core diameter is compatible with both manual and machine dispensers.Q: Where is the LLDPE stretch film typically stored, and why is it important?

A: For best performance, store the stretch film in a cool, dry area away from direct sunlight. This prevents heat or UV degradation, maintaining the materials tensile strength and clarity for prolonged usability.Q: What makes this stretch film eco-friendly and suitable for sustainable packaging?

A: The film is made from recyclable LLDPE, contains no additional coating, and is reusable, reducing environmental impact. Its recyclable nature ensures it aligns with eco-conscious packaging standards, making it a responsible choice for businesses.Q: Can the stretch film handle medium to heavy-duty loads, and is it water resistant?

A: Yes, this LLDPE stretch film is engineered for medium to heavy-duty loads, providing secure containment aided by its high tear and puncture resistance. It is also water resistant, safeguarding goods from moisture during transit or storage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging & Paper Category

Shrink Sleeve Label Manufacturer

Price 120 INR

Minimum Order Quantity : 200 Kilograms

Closure : Shrink Fit

Eco Friendly : YES

Material : Other, PVC Shrink Film

Finish Type : Glossy

Shrink Pouch

Price 120 INR

Minimum Order Quantity : 200 Kilograms

Closure : Openend, Heat Sealable

Eco Friendly : YES

Material : Other, Polyethylene (PE)

Finish Type : Glossy

Pet Shrink Labels Bottle

Price 120 INR

Minimum Order Quantity : 200 Kilograms

Closure : Shrinkfit (No separate closure)

Eco Friendly : Other, Yes, recyclable PET material

Material : Other, PET (Polyethylene Terephthalate)

Finish Type : Glossy Finish

Pof Shrink Film

Price 120 INR

Minimum Order Quantity : 200 Kilograms

Closure : Heat Sealed

Eco Friendly : YES

Material : Other, Polyolefin (POF)

Finish Type : Glossy

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS